GLOBALFOUNDRIES and Nikon Experts Discuss Scanner Flexibility and Matching to Enable the Roadmap

Presenting the Nikon view of the Lithography Roadmap at the 2011 LithoVision symposium earlier this year, Masato Hamatani, General Manager (GM) of Stepper Development, reported that while EUVL technology is progressing incrementally, there are still multiple engineering and infrastructural challenges before it is ready for high volume manufacturing (HVM) implementation. Hamatani commented that Nikon had anticipated this situation as well as the customer requirements for ArF immersion (ArFi) extension, and proceeded to explain that Nikon has developed comprehensive solutions to increase scanner performance, flexibility, and matching capabilities in order to extend ArFi to ~20 nm half-pitch. He noted that these enhancements include improvements to the scanner body and optics, as well as other areas to improve overall tool performance, and these were discussed in detail by other speakers later in the day.

Figure 1. Nikon anticipated customer requirements for ArF immersion (ArFi) extension (left image), and has developed comprehensive solutions to increase scanner performance, flexibility, and matching capabilities to extend ArFi to ~20 nm half-pitch.

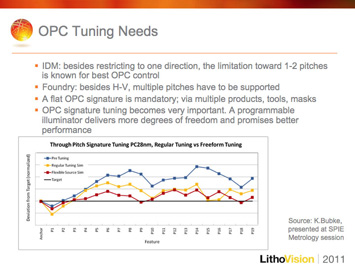

In a complementary presentation by Rolf Seltmann and Moshe Preil of GLOBALFOUNDRIES entitled "Transition of the Dresden Fab1 from IDM to Foundry in the Context of Low k1 Lithography," Dr. Preil, Manager of Emerging Lithography and Tools, discussed the differences in process complexity for integrated device makers (IDM) and foundries. Preil said that in the foundry case, half nodes must also be supported due to customer demand – especially for low power products, and added that process parameters such as resist and illumination must be unified as much as possible. He explained the key foundry drivers, stressing the heightened criticality of cost and timing, and noted that design flexibility necessitates flexible and dependable tools for this manufacturing environment.

Preil noted that IDMs can simplify their optical proximity correction (OPC) strategies by restricting themselves to features with a limited pitch range, and are also able to optimize across-chip linewidth variation (ACLV) by further restricting to unidirectional features. In contrast, foundries deal with many design houses and therefore, many horizontal/vertical orientations and multipitch conditions must be accommodated. He further explained that this flexibility means that optical proximity effect (OPE) signature tuning is critical to enable OPE matching across tools, reticles, and products. Preil then commented that at such low k1 values, controlling focus variation is the main objective of process control. Reiterating the message of foundry flexibility, he stressed the importance of portability of the focus setting (product-layer-tool), noting that running focus-exposure matrices on every combination is clearly not practical.

Figure 2. Preil explained the criticality of OPE signature tuning and a programmable illuminator to enable matching across tools, reticles, and products (left image). Preil stressed the importance of focus control and overall tool flexibility for foundries.

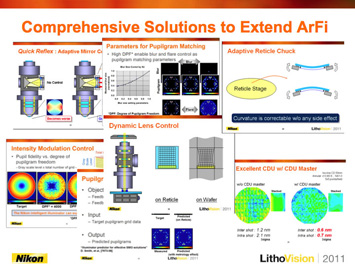

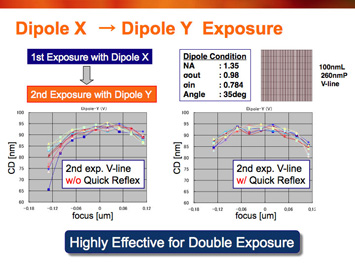

Next, Nikon explained several scanner imaging solutions to enhance tool flexibility and matching for ArFi extension. Yuichi Shibazaki, GM of Next Generation Development, highlighted among other topics that Nikon is improving thermal aberration control, especially of astigmatism, with the new Quick Reflex system. He went on to explain that this adaptive-mirror control system will be especially effective for controlling CD through focus with double exposure techniques where, for example, dipole-X illumination is used for the 1

Figure 3. The Quick Reflex system is highly effective for maintaining CD-through-focus control with double exposure conditions (left image). The Nikon intelligent illuminator provides up to 100,000 DPF to ensure freeform source fidelity to a target.

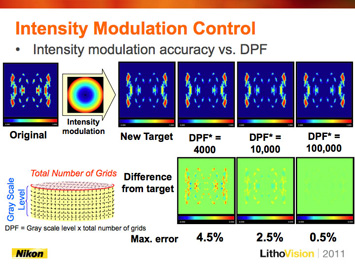

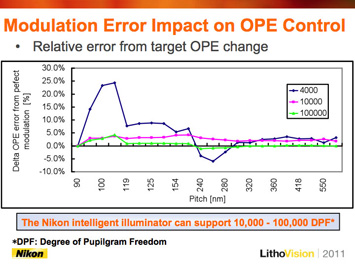

Tomoyuki Matsuyama, Imaging Technology Project Leader, then provided insight on "Advanced Imaging Solutions" to support flexibility and enhance OPE matching capabilities. Matsuyama reported that OPE sensitivity to pupilgram changes was studied using both intensity modulation and distortion modulation of the pupilgram. From that work, intensity modulation was determined to be a suitable parameter for OPE control. He cautioned however, that its accuracy is highly dependent upon the degree of pupilgram freedom (DPF) of the scanner’s illuminator, as well as the positional control of the pupilgram in the pupil plane.

Figure 4. High DPF supports optimal OPE matching for increased tool flexibility (left image). Freeform source implementation will be supported by a comprehensive solutions package from Nikon

Matsuyama said that the DPF (gray scale level × total number of grids) is an important figure of merit for the illuminator pupil, showing a clear impact of degree of pupilgram freedom on pupil fidelity as well as intensity modulation control accuracy. He went on to explain that the Nikon intelligent illuminator can support 10,000 to 100,000 DPF, highlighted the impact of modulation error on OPE control, and noted that DPF larger than 10,000 may be required for optimal OPE matching using freeform illumination. He further reported that high DPF also enables Nikon blur and flare control, which are additional pupilgram matching parameters to provide further scanner flexibility.

Matsuyama summarized his informative presentation by noting that the Nikon intelligent illuminator provides a high degree of pupilgram freedom to ensure freeform source fidelity and support OPE matching, thereby increasing tool flexibility. He also reported that freeform source implementation will be supported by a comprehensive solutions package from Nikon.